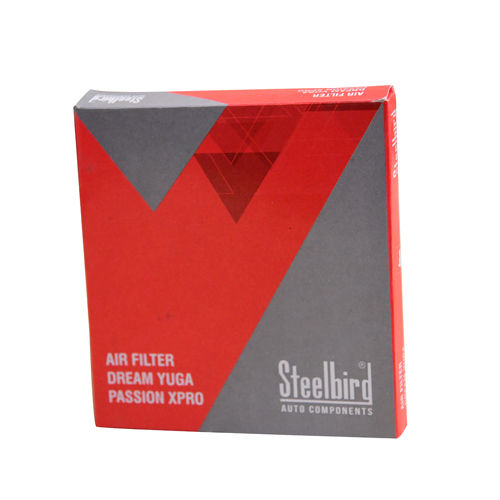

Printed Mono Box

Product Details:

- Shape Rectangle

- Size Small To Large

- Color Blue

- Material Paper

- Printing Color Sky Blue

- Paper Type Corrugated Board Art Paper Coated Paper Paperboard Fancy Paper Wood-Free Paper Specialty Paper Kraft Paper Duplex Paper Glossy Art Paper

- Finish Printed

- Click to View more

Printed Mono Box Price

- 5000 Box

Printed Mono Box Specification

- Blue

- Sky Blue

- Printed

- Shape Style Size Color Logo

- Small To Large

- Corrugated Board Art Paper Coated Paper Paperboard Fancy Paper Wood-Free Paper Specialty Paper Kraft Paper Duplex Paper Glossy Art Paper

- Rectangle

- Paper

Printed Mono Box Trade Information

- 1 Box Per Week

- 10-15 Days

- Yes

- Free samples are available

- As Per Requirement

- North India

Product Description

We maintain a strict quality assurance policy for our printed mono box which as fabricated with standard quality parameters, both in compliance with national and international levels. We have a stringent quality checking procedures to ensure every raw material stands on the ground of specific parameters. Our quality parameters do not just limited to testing of printed mono box but also other aspects of the operation. For example, we are particular about delivery of products, ensuring that the ordered quantity of packaging boxes should be delivered at the right place at the right time.

FAQs of Printed Mono Box:

What is mono container box?

Mono containers are containers utilized for minimized bundling of items. They are exceptionally adaptable and works with an enormous number of uses across enterprises.

What number of sorts of containers are there?

Most containers principally come in two organizations - collapsing containers and unbending box containers. Collapsing containers are those which are fabricated from a solitary sheet board. It very well may be paperboard, folded board or fiberboard. A solitary sheet is kick the bucket slice as per a layout and is then collapsed to make a crate or a plate.

What is contrast among container and box?

A container is commonly produced using a more slender material than boxes, similar to paperboard. Containers are utilized as external bundling for a few kinds of items, like beauty care products and enhancements.